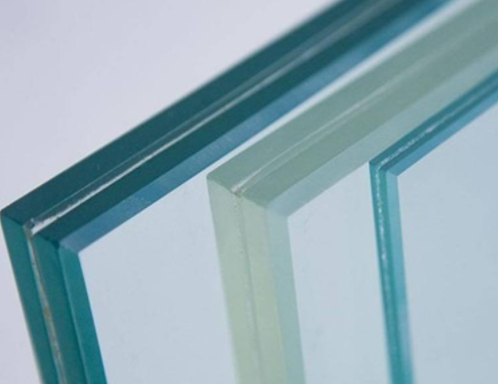

Iglasi elayitiweyo yenziwe ngamaleko amabini okanye ngaphezulu eglasi ecaba (okanye iglasi egobileyo) efakwe ifilimu yePVB kwaye yenziwe kwiglasi yokhuseleko lomgangatho ophezulu ngoxinzelelo oluphezulu. Ineempawu zokungafihli, amandla omatshini aphezulu, ukukhuselwa kwe-UV, ukugqunywa kobushushu, ukugqunywa kwesandi, ukungqinwa kwebhulethi, ubungqina bokudubula, njl njl. Ngokuqhelekileyo, i-PVB interlayer isetyenziselwa i-interlayer yeglasi elaminethiweyo kwizakhiwo. Ifilimu ye-PVB inomsebenzi wokudambisa wokucoca amaza omsindo (ukunciphisa i-vibration amplitude yesandi kunye nokuhanjiswa kwevolumu).

Imigangatho emibini umatshini weglasi elaminethiweyo

inokusetyenziswa

Imveliso yeFangding glue eziko, ukuqinisekiswa komgangatho.

Izilumkiso zenkqubo yokuvelisa iglasi elaminethiweyo:

1. Ukucutshungulwa kweglasi, i-EVA film lamination

Sika iglasi kwisayizi efunekayo kunye nokuma, kwaye upholise umda weglasi (enokuthi ithintele ngokufanelekileyo umda weglasi ukusika i-plate ye-silicone); Coca iglasi (sula uthuli, iincinci ezincinci kunye nokungcola okuseleyo kwiglasi, kwaye usule iglasi ngotywala). Akufunekanga kubekho ukungcola, iimpawu zamanzi okanye iimpawu zeminwe kumphezulu weglasi; Lungiselela ifilimu ye-EVA ukuba inqunyulwe kwisayizi efanelekileyo, kwaye ikliphu ifilimu phakathi kweglasi kunye neglasi ye-lamination.

2. Ukulungiselela ngaphambi kokungena eziko

Beka iziqwenga zeglasi kwisakhelo sesitovu (Qaphela: kufuneka kubekho i-gap eyaneleyo phakathi kweeglasi ukukhusela ukunamathela) i-nozzle yokufunxa ye-silicone plate ayifanele ivalwe, ngaphandle koko umoya kwi-plate ye-silicone awukwazi ukukhutshwa ngokupheleleyo. Ngaphandle kweglasi yenkunkuma (kungcono ukusebenzisa igridi yokukhupha okufanelekileyo), tywina ipleyiti ye-silicone phezulu nangaphantsi, uvule ipompo yokucoca, kwaye ukhuphe umoya kwisitya se-silicone. Ngaphambi kokungena kwisithando somlilo, qiniseka ukuba ukhangele ukuba isikhwama se-vacuum sivuza, ukuba kukho, Nceda ulungise ngokukhawuleza (ukuba kukho ukuvuza komoya kwi-plate ye-silicone, ayikwazi ukufudumeza kwisithando somlilo).

3. Ukufudumeza kweglasi

Gcoba ishelufu yeglasi kwisithando somlilo seglue, kwaye usethe ixesha elifunekayo kunye nobushushu ngokweglasi efunekayo.

4. Iglasi ephuma eziko

Emva kokufudumeza kunye ne-insulation, xa iqondo lokushisa kwibhokisi liya kuba ngaphantsi kwe-90 ℃, vula umnyango kwaye ukhuphe isakhelo seglasi. Xa ubushushu behla ukuya malunga ne-30 ℃, vula ipleyiti ye-silicone kwaye ukhuphe iglasi.

Ixesha lokuposa: Jul-08-2022